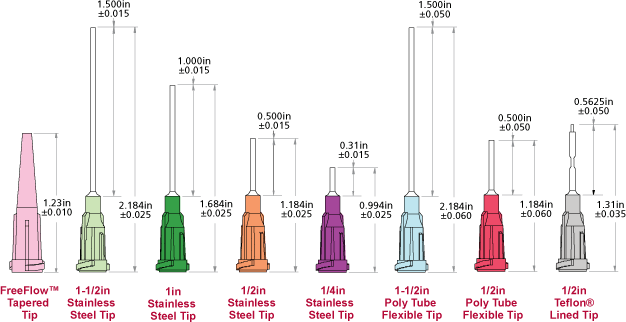

In the fluid dispensing process, it is necessary to select the proper dispense tip for the syringe. The type of tip required is determined by the type of fluid that is being dispensed. Syringe dispensing tips can be made of many materials including stainless steel, Teflon, and polypropylene.

The size (length, gauge, and shape) of the dispense tip must meet the exact dispensing requirements of the project to ensure precision of the fluid deposit and the performance of the dispense system overall.

When choosing a dispense tip length and gauge size for syringe dispensing, follow these guidelines:

• Use the shortest length and largest gauge possible- longer dispenser tips and smaller gauges cause unnecessary backpressure.

• Reducing length by as little as .5 inches (1.27cm) and increasing gauge size by one size will drastically reduce backpressure in the syringe.

• If stuck in a particular length or gauge size due to the constraints of the application use thin wall cannula (tubing). Thin wall tubing increases the inner diameter while maintaining outside diameter without compromising tubing strength. This also will drastically reduce backpressure in the syringe.

• If a stainless steel dispense tip is needed use the shortest length possible (1/4” length).

• Using the shortest tip possible will further reduce your cycle time.

Are you still unsure of how to proceed? Choosing the right dispense tip is something that you absolutely need to get right. Please contact Fishman Solutions for more information or if you need help.