From 1975-2010 air pressure was the method of choice to dispense fluid from a syringe reservoir. Millions of dollars were spent trying to combat the erratic fluctuation of air supply from compressors plum through the manufacturing facility. One of the biggest firefights in the fluid dispensing industry eventually led to the demise of the air dispenser.

In the 1960’s, prior to the adhesive bonding revolution, manufacturing fluids were dispensed from hospital style syringes.

In the 1970’s, scientists began to conquer the technology behind adhesive bonding. As a result, the adhesive bonding revolution began. Under assault, mechanical bonding devices such as pop rivets and screws were being rapidly replaced with adhesive. Speed of assembly, size, and weight were the main driving factors of the revolution. Consequently, the timed air dispenser was developed from the growing desire to apply the adhesives in a manufacturing facility. Over the years the look and feel of the air dispenser changed but the core technology remained the same.

The core technology of the air dispenser combines compressed air to an air solenoid controlled by a simple timing circuit creating an open close cycle. The compressed air flows to the syringe reservoir filled with the assembly fluid on the open cycle and dissipates on the close cycle. Increasing and decreasing compressed air pressure and the open close cycle time delivers a wide volume range of assembly fluid deposits. 35 years later the same core technology is used on all air dispensers.

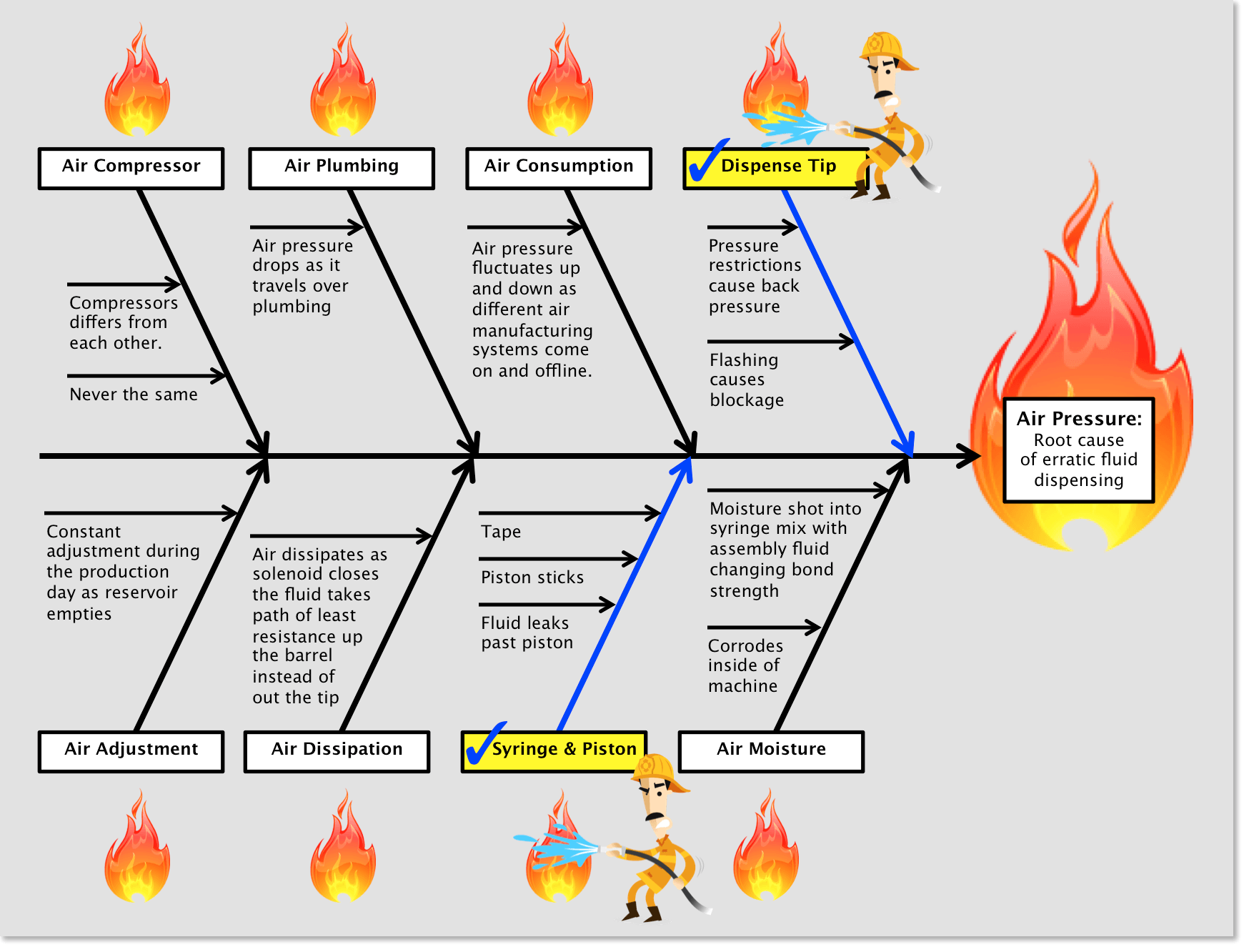

So begins the greatest firefight in fluid dispensing history. Firefighting is a term used by quality control personnel when problem solving is focused on a byproduct of a problem’s root cause as opposed to the root cause itself. Firefighting may solve a single problem but will not solve all of the problems associated with the root cause. Also, there is no guarantee that the problem will not reoccur if the root cause still exists. Quality control tools such as the Ishikawa diagram were invented to isolate the root cause of the problem. Eliminate the root cause problem and all byproducts are eliminated instantly. Miss the root cause and you may make the same mistake the air dispenser manufacturers made spending 35 years wasting money firefighting byproduct problems.

Hindsight being 20/20 we can map all the problems with air dispensing using an Ishikawa diagram isolating the root cause of erratic assembly fluid dispensing. The result? Air pressure is the root cause creating multiple byproduct problems. The byproduct problems began burning the first day air dispensers were introduced to the manufacturing facility. Over the years as technology advancements miniaturized consumer products the fires blazed to 5 alarm status. Thus, air pressure manufacturers failing to recognize the root cause began the wasteful process of firefighting byproduct problems.