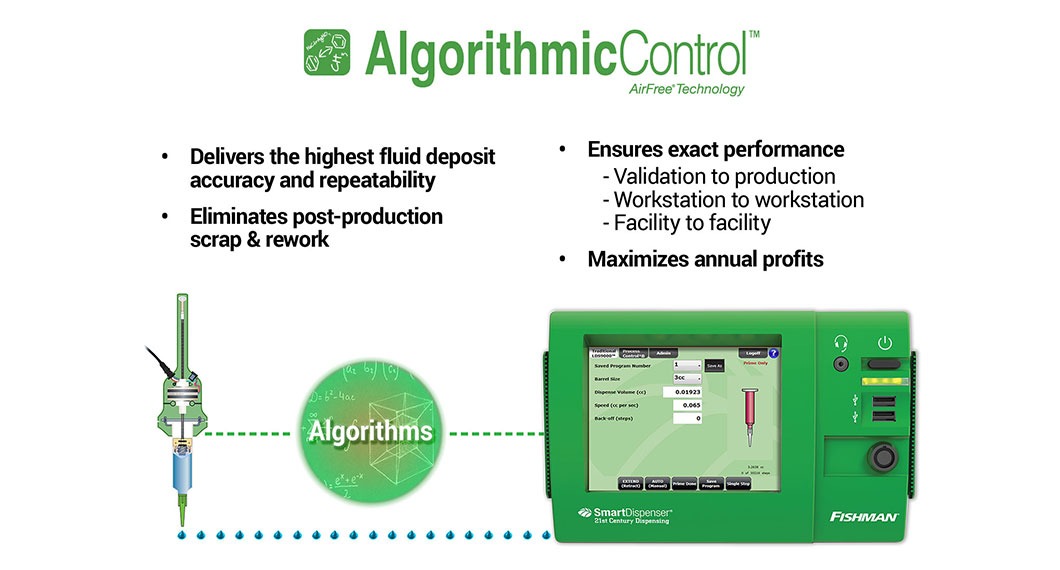

The SmartDispenser® from Fishman® Corporation is used in the application of assembly fluids for a very wide range of industries and products. It features AlgorithmicControl™ and patented AirFree® Technology; innovations that enable manufacturers to assemble products without relying on unpredictable compressed air and error-prone human input. The precision and control gained with the SmartDispenser® greatly improves the assembly process, which increases productivity, yields and profits.

The SmartDispenser® from Fishman® Corporation is used in the application of assembly fluids for a very wide range of industries and products. It features AlgorithmicControl™ and patented AirFree® Technology; innovations that enable manufacturers to assemble products without relying on unpredictable compressed air and error-prone human input. The precision and control gained with the SmartDispenser® greatly improves the assembly process, which increases productivity, yields and profits. The SmartDispenser® from Fishman® Corporation is used in the application of assembly fluids for a very wide range of industries and products. It features AlgorithmicControl™ and patented AirFree® Technology; innovations that enable manufacturers to assemble products without relying on unpredictable compressed air and error-prone human input. The precision and control gained with the SmartDispenser® greatly improves the assembly process, which increases productivity, yields and profits.

The SmartDispenser® from Fishman® Corporation is used in the application of assembly fluids for a very wide range of industries and products. It features AlgorithmicControl™ and patented AirFree® Technology; innovations that enable manufacturers to assemble products without relying on unpredictable compressed air and error-prone human input. The precision and control gained with the SmartDispenser® greatly improves the assembly process, which increases productivity, yields and profits. Increases fluid deposit repeatability by as much as +/-20% - 30%* over traditional compressed air systems. SmartDispenser®MINI™ allows for algorithm-driven motor control that provides positive displacement from a syringe.*Repeatability results are fluid dependent

Increases fluid deposit repeatability by as much as +/-20% - 30%* over traditional compressed air systems. SmartDispenser®MINI™ allows for algorithm-driven motor control that provides positive displacement from a syringe.*Repeatability results are fluid dependent Increases fluid deposit repeatability by as much as +/-20% - 30%* over traditional compressed air systems. SmartDispenser® is an Industry 4.0 device that enables integration, data exchange, decision-making and automatic daily production data reporting.*Repeatability results are fluid dependent

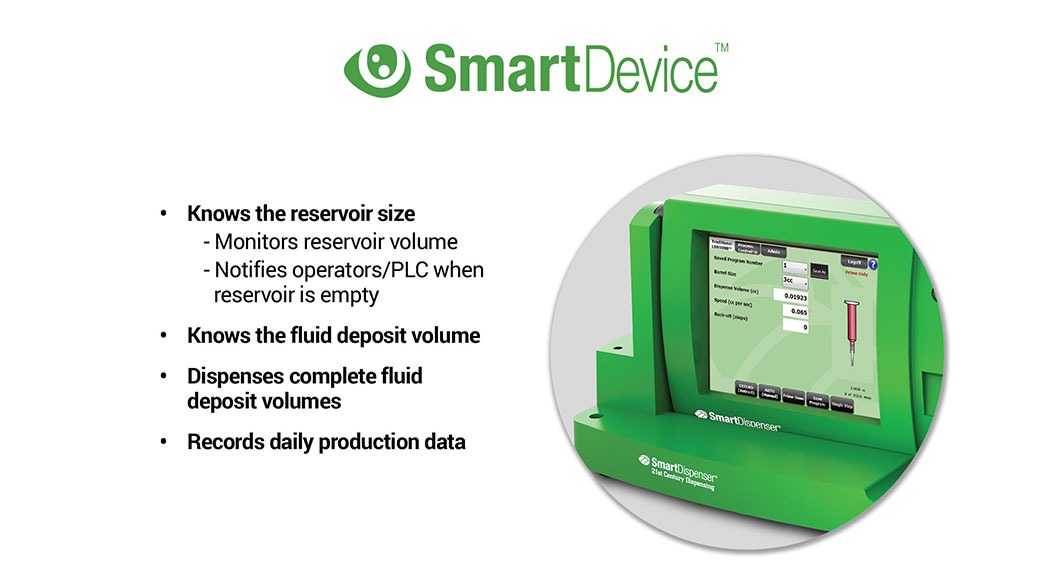

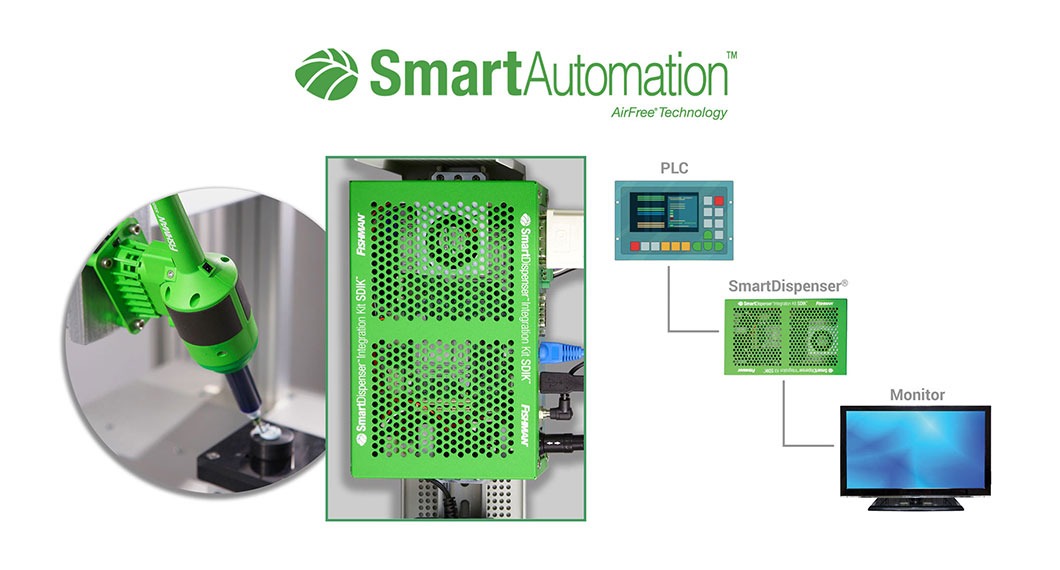

Increases fluid deposit repeatability by as much as +/-20% - 30%* over traditional compressed air systems. SmartDispenser® is an Industry 4.0 device that enables integration, data exchange, decision-making and automatic daily production data reporting.*Repeatability results are fluid dependent When the SmartDispenser® is attached to another device such as an industrial robot, that device becomes a smart device. This helps to deliver increased fluid deposit repeatability, Industry 4.0 capabilities, 4th axis motor (fluid) control and automatic reporting of daily production data.

When the SmartDispenser® is attached to another device such as an industrial robot, that device becomes a smart device. This helps to deliver increased fluid deposit repeatability, Industry 4.0 capabilities, 4th axis motor (fluid) control and automatic reporting of daily production data. The SmartDispenser® 19 Inch Din Rail Integration Kit allows the SmartDispenser® to be mounted into the electronic cabinet of any automation system.

The SmartDispenser® 19 Inch Din Rail Integration Kit allows the SmartDispenser® to be mounted into the electronic cabinet of any automation system. The robust syringe piston design of Genius® AirFree® Syringes makes them a superior fluid storage container. As such, they provide longer storage life and prevent contaminates such as moisture and air bubbles from entering the fluid during the dispensing process. Genius™ syringes can be deployed using either AirFree® or compressed air fluid dispensing systems.

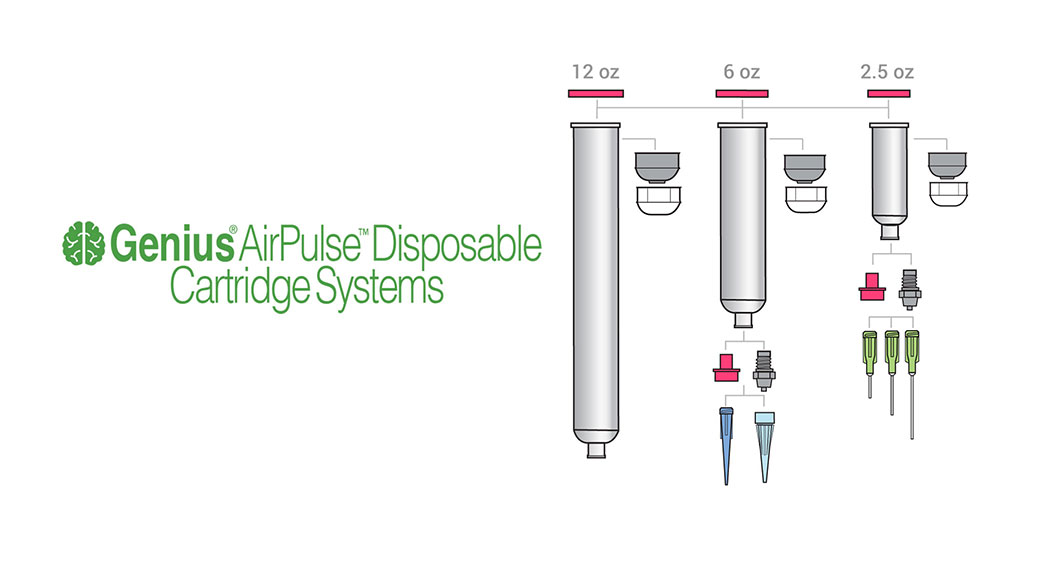

The robust syringe piston design of Genius® AirFree® Syringes makes them a superior fluid storage container. As such, they provide longer storage life and prevent contaminates such as moisture and air bubbles from entering the fluid during the dispensing process. Genius™ syringes can be deployed using either AirFree® or compressed air fluid dispensing systems. Genius® AirPulse™ Disposable Cartridge Systems are ideal for large volume fluid dispensing, such as potting, beading or screen printing. They can be used with handheld dispense guns, and function as a fluid reservoir when employing a SmartValve™.

Genius® AirPulse™ Disposable Cartridge Systems are ideal for large volume fluid dispensing, such as potting, beading or screen printing. They can be used with handheld dispense guns, and function as a fluid reservoir when employing a SmartValve™. Genius® PosiLok™ Disposable Dispensing Tips are available for use with any SmartDispenser®, SmartValve™, DualDrive™ or SmartAutomation™ system. All Genius® tips are produced in our own silicone-free facilities, and are subjected to stringent quality control inspections throughout the entire manufacturing process.

Genius® PosiLok™ Disposable Dispensing Tips are available for use with any SmartDispenser®, SmartValve™, DualDrive™ or SmartAutomation™ system. All Genius® tips are produced in our own silicone-free facilities, and are subjected to stringent quality control inspections throughout the entire manufacturing process. SmartValves™ let production engineers numerically control the open and close motion in inches via the SmartDispenser's® HMI helping them to provide a high level of fluid control. SmartValves™ also enable algorithm-driven motor control that replaces the need for compressed air. In addition, they permit inline dispense head removal which greatly reduces production downtime during valve maintenance.

SmartValves™ let production engineers numerically control the open and close motion in inches via the SmartDispenser's® HMI helping them to provide a high level of fluid control. SmartValves™ also enable algorithm-driven motor control that replaces the need for compressed air. In addition, they permit inline dispense head removal which greatly reduces production downtime during valve maintenance. DualDrive™ Systems are ideal for fiber optic MT and MTM connector assembly or job shop applications. Fluid volume is set numerically via the SmartDispenser's® HMI. DualDrive™ Systems also permit algorithm-driven motor control that ensures a high level of fluid deposit repeatability.*Repeatability results are fluid dependent

DualDrive™ Systems are ideal for fiber optic MT and MTM connector assembly or job shop applications. Fluid volume is set numerically via the SmartDispenser's® HMI. DualDrive™ Systems also permit algorithm-driven motor control that ensures a high level of fluid deposit repeatability.*Repeatability results are fluid dependent