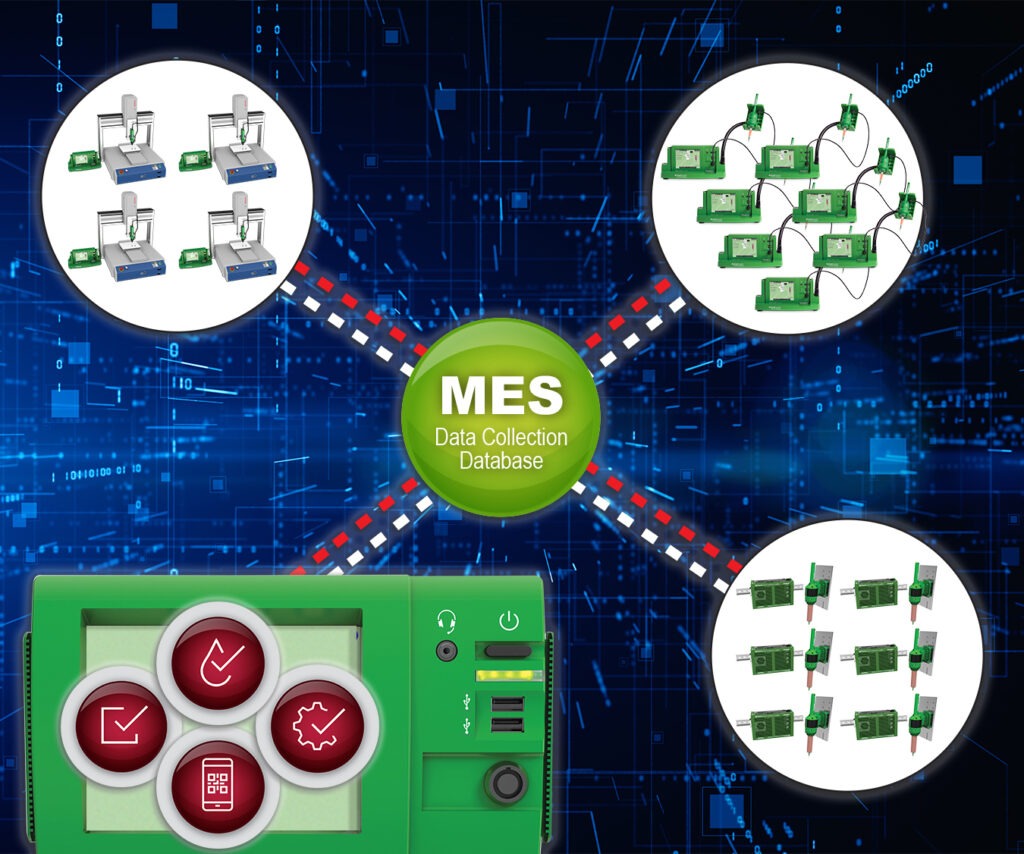

The SmartDispenser® is designed to store data, make decisions, and execute commands. When you examine its SmartNetworking™ capabilities you quickly learn that it can also provide you with a straightforward and effective way to communicate with your production equipment by connecting it to your MES system.

Fishman® can help you do this by working with you to create an MES Connection Package to the SmartDispenser®. To start the process simply put together a design document or “wish list” of what you want to accomplish. When we receive it, our engineers will review it with you, initiating a back and forth exchange of ideas until it meets with your complete satisfaction. Next, we’ll put together a quote for your MES Connection Package. Once approved, we’ll work with you to implement your newly created connection.

The SmartDispenser® was made with you in mind

If your production facility has Windows 11 installed, the SmartDispenser® utilizes a Microsoft-approved off-the-shelf single board computer (SBC). There’s nothing custom about this off-the-shelf solution, which makes validation far easier. With the SmartDispenser®, you essentially have a laptop or tablet, so when you connect it to your local secure server, it employs the same protocols as does any Microsoft Windows desktop/laptop/tablet used at your company.

The connection opens the door to doing more

Your MES Connection Package simulates the typical production machine customizations most manufacturing engineers execute with a PLC. You can add even more capabilities to it with SmartApps™ for Auto Program Load, Assembly Fluid Verification, Raw Material Verification, and Operator Training Verification. With the Connection Package and these SmartApps™, your SmartDispenser® will be able to communicate with, and be controlled by your MES system. Having these capabilities not only eliminates costly PLC programming, but they also simplify the entire process while providing valuable production data available in real time for management to review and, if necessary, act on.

“Look Ma, next to no hands!”

More remarkable, with the SmartApps™ listed here, the communication between the SmartDispenser® and your MES system is accomplished with next to no human intervention, thereby avoiding the errors that come with it. All that’s necessary is for the operator to scan a barcode, which provides the MES system with the information needed to execute the commands. With these intelligent innovations from Fishman®, you have a smart way to maximize the investment you’ve already made in your MES system, and a great way to save money by lowering programming and hardware costs, and by increasing production efficiency.

Nothing gets lost in translation

What follows are some of the ways in which the SmartDispenser® with AirFree® Technology can automate enterprise-wide communication, ensuring that all those who need to be kept in the loop receive the necessary information.

Management Communication

Automatically email daily production data to the production manager

- The SmartDispenser®, via a secure local server, will automatically email detailed daily production data to the production manager.

Automatically export daily production data to a drive on a secure local server

- The SmartDispenser® will automatically save a copy of the daily production data to a drive on a server that can be shared by management.

Automatically export daily production data to the local MES System

- The SmartDispenser® will automatically save a copy of the daily production data to the MES system database.

Two-Way Communication

Allows production data to be sent from the SmartDispenser® to the local MES System, which empowers the MES System to send executable commands back to the SmartDispenser®

Command and control

- For example, the SmartDispenser® sends a product part number and an adhesive part number to the MES system. The MES system can then choose and load the appropriate dispense program onto the SmartDispenser®.

- The SmartDispenser® also has an SQL database on board, which allows the SmartDispenser® to send command, control, and reporting queries to the MES system.

Learn more to be smarter

By specifically designing various unique capabilities and adding them into AirFree® Technology, the SmartDispenser® becomes an even greater force of intelligence for manufacturers around the world. For more information about the MES Connection Package and the SmartApps™ designed to further improve communications be sure to visit Fishmancorp.com.