The SmartDispenser® stabilizes the dispense process with proper reporting easing production equipment validation for the assembly of medical devices. This saves hours of equipment validation time, reducing the equipment validation process cost.

The following 7 steps reduce the cost of validating fluid dispensing equipment systems:

Step 1 – Stabilize the drive system controlling the amount of fluid dispensed

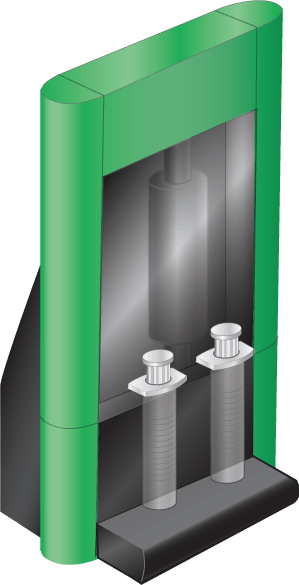

The linear drive system replaces erratic compressed air inside the syringe. This guarantees the forward and reverse motion of the dispense cycle will be exactly the same every cycle. Electricity replaces air assuring that every linear drive system performs exactly the same.

Step 2- Replacing the traditional air compressor and plumbing system with electricity

The SmartDispenser® control center uses a universal power supply and electronics, assuring that the electrical current to every linear drive system is exactly the same. The stable drive system and stable power guarantees every SmartDispenser® system dispenses fluid identical to the next. This design provides the foundation allowing medical device manufacturers to use one dispense program for a particular device on all SmartDispenser® systems worldwide regardless of location. Every workstation and every manufacturing facility performs exactly the same.

Step 3- Stabilize the syringe filling process

The SmartDispenser® syringe filling system is an automated air free filling system using an electronic actuator combined with the meter and cylinder. The SmartDispenser® communicates the fill volume via a USB electronic control tether allowing the syringe filler to automatically select the fill height. By eliminating human intervention the syringe fill volume is guaranteed to be the same on every syringe within a fraction of a cubic centimeter. An encoder confirms the proper volume was dispensed.

Step 4- Perform a capabilities study

A capabilities study quantifies the impact of the fluid on the SmartDispenser®’s performance. Because the SmartDispenser® pushes on a column of fluid, different fluid dynamics have different impacts on the system performance. With the drive system, power, and syringe filling stabilized, the impact of the fluid is minimized and quantifiable. The capabilities study focuses on the target fluid deposit weight and the +/- tolerance. The SmartDispenser® is designed to communicate with an AND Analytical Weighing Sensor. Activate the weighing sensor option in the software, determine the dispense program, input the target weight, perform a weight study on a full syringe and the SmartDispenser® will automatically record the weight data in an Excel CSV file on the SmartDispenser® hard drive. Import into Excel for statistical analysis.

Step 5- Create a master capabilities report

Include the dispense program, testing criteria, and quantified study of the SmartDispenser®’s capabilities within the chosen assembly fluid. The master capabilities report is released to quality control, which will be the control document for future SmartDispenser® calibrations.

Step 6- Create a program specification

This specification outlines the dispense program to be used for the particular medical device being assembled. The specification is released to production which instructs how to program each SmartDispenser®, ensuring all SmartDispenser®s for a specific product are programed exactly the same.

Step 7- Monitor and verify documented traceability from the point of dispense

The SmartDispenser® automatically records the dispense program used to assemble the medical device in an Excel CSV file saved on the hard drive. The production manager can verify post assembly process that the SmartDispenser® operator used the specified dispense program to assemble the medical device.