Assembly fluid dispensing began with pneumatics. Hand-held, bench-top, automated workstation, diaphragm, spool, needle, and piston valve dispensers were air driven, meaning that they depended on a column of air under pressure to force assembly fluid through the dispensing tip and onto a substrate.

The pneumatic fluid dispensing process is still used across many industries, however air-driven dispensers are on a decline because they often result in reliability and quality control problems including variations in viscosity and dot size, dripping and waste of the material, and changes in homogeneity. These conditions challenge the accuracy and repeatability of fluid dispensing systems.

Fluid dispensers that rely on air pressure are unreliable due to fluctuations in air pressure. Pressure drops and volumetric displacement are a result of the plumbing between the air compressor and workstation. When violent air pulses come into contact with the assembly fluid it can result in turbulence, heat, and changes in viscosity. This undermines the ability of air-driven dispensers to deliver prescribed amounts of material consistently. Fluid dispensing accuracy and repeatability is challenged.

Fortunately there is now an answer to the problems that plague conventional dispensers which eliminates any and all use of pneumatics which is the root cause of the problem. Systems based on air-free technology are gaining wider use in dispensing adhesives, solder paste, and other fluids.

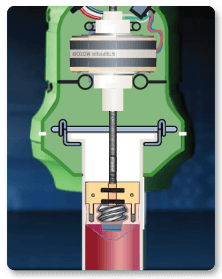

Fishman’s answer to fluid dispensing problems caused by air pressure is the SmartDispenser®. It features a proprietary dispensing system that offers a superior level of process control without the limitations of other types of dispensers on the market. The SmartDispenser® uses AirFree® linear-drive dispense technology to achieve the highest repeatability when dispensing assembly fluids. The fluid handling technology allows manufacturers to establish one dispense program globally, withi no change to fluid deposits. It ensures that a dispense in the U.S. will perform exactly as a system in China as long as the same program, assembly fluid, reservoir, and dispense tip are employed in both locations. In addition, SmartDispenser® AirFree® technology eliminates fluid waste, rework, rejects, and costly air compressors to maximize profitability. The SmartDispenser® fluid dispensing system AirFree® dispensing series includes a handheld benchtop, benchtop automation, and an automation system.