The solder paste dispensing process began with pneumatics. Pneumatic dispensers were at one time the only method available for hand-held and automatic dispensing of solder paste. Any device used to dispense solder paste (hand held gun, automated workstation, diaphragm, spool, needle, piston, etc.) depended on a column of air under pressure to force material through a dispensing tip and onto a substrate. Unfortunately, this air pressure caused the device to deliver prescribed amounts of solder paste inconsistently due to heat, moisture, fluctuations in air pressure, contamination, and changes in viscosity. It was especially a problem when small amounts of solder paste were required by high density electronic circuitry (typically, less than a milligram). Because demand for precise volume control and repeatability continued to grow, it led to the development of alternative solutions in dispensing.

The most notable alternative solution in solder paste dispensing was the auger valve. However, auger valves have severe limitations. Using an auger valve, the material is stressed by the motion of the auger. The result can be a change in both temperature and homogeneity, which can impact viscosity and the amount of solder paste dispensed as well as the quality of the dot.

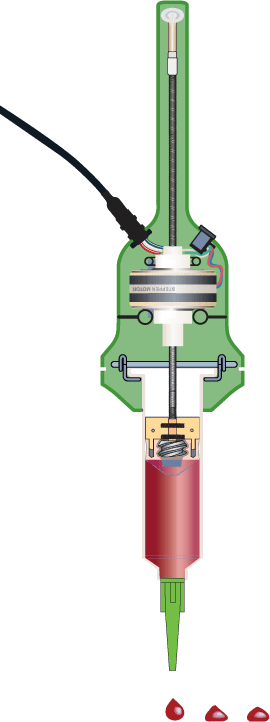

The best option for solder paste dispensing is AirFree® linear drive technology. AirFree® linear drive technology provides high repeatability without concern for viscosity and the volume of paste remaining in the syringe. The amount of solder paste delivered (dot after dot after dot) is consistent. The technology also provides significant savings in material cost due to the ability to pre-package syringes with larger amounts of paste than is possible with other types of dispensers.

The Fishman SmartDispenser® Solder Paste Dispensing Series offers advanced automation control through visual verification and real-time reporting at the point-of-dispense. It utilizes proven AirFree® technology and offers accurate and repeatable liquid displacement without the headaches associated with pneumatic systems requiring trial and error adjustments of knobs and dials. The SmartDispenser® solder dispensing system combines Fishman’s AirFree® technology with a Windows® 7 operating system and a platform for downloadable software, service and training Apps. It is ideally suited for solder dispensing applications in the electronics, medical device, automotive, telecommunications and defense industries as well as for other general manufacturing processes.